Applicable Materials: Carbon steel plate, stainless steel plate, aluminum plate, copper plate, titanium alloy, non-ferrous metals, rubber/plastic materials, marble, graphite, etc.

Workpiece Types: Various flat plate components.

| Parameter Item | Detailed Specification |

| Equipment Model | SMYJ - RLW1000 |

| Processing Width | 1000 mm (Customizable) |

| Processing Thickness | 1 - 80 mm |

| Lifting Method | Four-Post Synchronized Lifting (Digitally Set) |

| Abrasive Belt Linear Speed | 18 m/s (Optional Variable Frequency Speed Control) |

| Polishing Wheel Linear Speed | 20 m/s (Optional Variable Frequency Speed Control) |

| Conveyor Speed | 2 - 11 m/min (Variable Frequency Adjustable) |

| Auxiliary Equipment | Wet Dust Collector or Industrial Pulse Dust Collector |

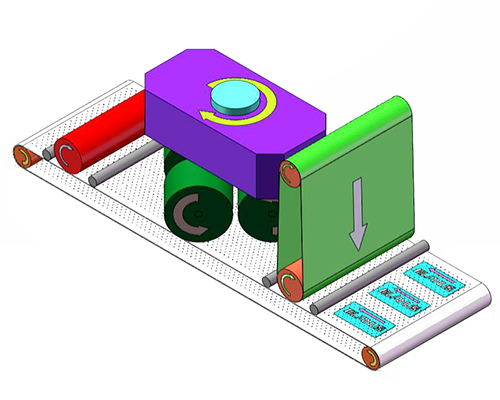

| Equipment Combination | Wide abrasive belt + polishing wheel + roller brush (customizable) |

To ensure stable conveying of workpieces with different materials, the following professional solutions are provided:

**Strong Permanent Magnetic Adsorption**

- Applicable to: Ferromagnetic materials such as carbon steel.

- Requirement: Workpiece dimensions ≥ 10mm × 10mm.

**Vacuum Negative Pressure Adsorption**

- Applicable to: Non-magnetic materials such as stainless steel, aluminum, and copper.

- Requirement: Workpiece dimensions ≥ 50mm × 50mm.

|  |